Cement

PREHEATER BUILDING ( CONCRETE / STEEL)

- The loading on Preheater structure is from static dead and live loads from the self-weight of cyclones, Refractories and Raw meal dust load.

- The dynamic loads are due to earthquake, wind. The Preheater tower is tallest structure in cement plants and carrying heavy loads.

- Preheater structures can be designed as steel or concrete constructions.

KILN SUPPORTS DESIGN

- Kiln is a nerve center for cement plants.

- It operates continuously for 24 hours till periodic planning shut down takes place.

- Kiln Supporting piers are solid mass or Hollow depending on the height.

- Loads of static, dynamic loads and Temperature and all vertical, Horizontal loads are considered while designing Kiln piers.

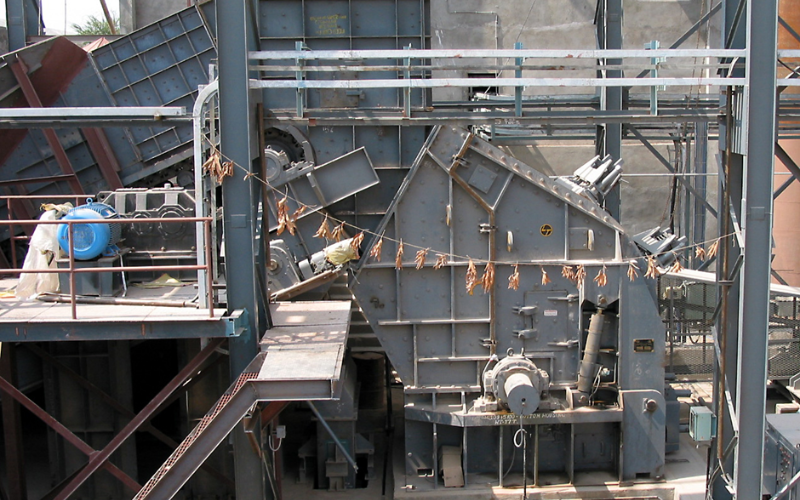

CRUSHER FOUNDATION

- During operation of crusher, eccentricity of rotating mass can develop causing unbalanced forces.

- The foundations of crushers are designed ensuring stability against overturning and keeping soil pressures within permissible limits

ROLLER PRESS FOUNDATION

- Roller press is installed in grinding installations to cut down energy consumptions in the grinding unit.

- In addition to vertical load there is a lateral force along axis perpendicular to rotating axis of press.

- It is advisable to isolate press supporting structure from the main mill building structure.

VRM FOUNDATION

The vertical roller mill is generally a balanced machine. Since the suppliers specified minimum weight of foundation to be provided irrespective of soil parameter, the mill foundations are designed based on suppliers specifications and soil conditions. Mill foundations are designed ensuring vibrations free operations.

BALL MILL FOUNDATION

Raw mill, Cement mill and Coal mill foundations are designed based on the static and dynamic factors are provided by the Ball Mill suppliers For this kind of ball mills, very high horsepower motor is required. Motor foundation is separately provided independent of mill foundation and is to be suitable design

RAW MEAL SILO

Raw meal silo structure are designed for blending and storage of raw meal. Types of Silos

- Continuous flow flat bottom silo.

- Inverted cone silo.

Types of silos are decided based on the capacities and economical point of view suitable for site conditions.